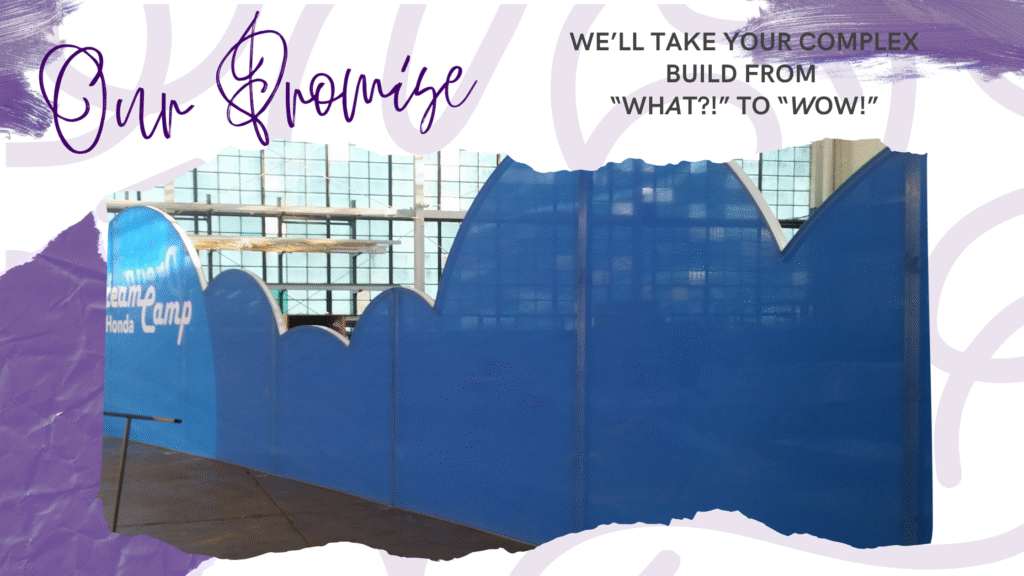

On the trade show floor, your work is your reputation. You can design and build the most beautiful frame in the world—but if the graphics look sloppy, faded, or ill-fitting, guess what people notice?

Spoiler: it’s not the craftsmanship of your frame.

Here’s the thing we all know, but you may still be gambling on—it’s not just what fabric you use, it’s how it’s finished and printed that separates a perfect display from a panic-inducing install.

Finishing & Printing: The True Q.C.

A high-end Quality fabric graphic isn’t just “nicer material.” It’s the cutting, sewing, and printing process that makes it perform on the show floor. Finishing determines how well the fabric fits the frame, whether seams are visible, and is key for installing to go smoothly.

Printing determines whether colors are vibrant, graphics sharp, and branding stays accurate under every kind of lighting.

If corners are cut, you’re setting yourself (and your client) up for problems.

Why Risk It?

We’ve all been there—standing on the show floor, one coffee in, already sweating, staring at a fabric graphic that technically should work, but doesn’t. Here’s what happens when finishing and printing aren’t done right:

1. The Midnight Sag

Went on easy at setup (maybe a little too easy) looking good… until morning, when gravity decides to get involved. Precision cutting and stitching keep graphics tight from install to teardown—no surprise hammocks.

2. The Color Surprise

That perfectly approved “corporate blue” somehow doesn’t match between graphic panels under the hall lights. High-end printing lays down saturated, accurate colors that stay true from proof to show floor to product photos and attention to detail to make sure fabric grain change doesn’t turn your perfect blue into something washed out and unmatching.

3. The Imperfect Cut-out:

Let’s face it, from drawing board to show floor there is a lot of room for error. But with expert finished fabrics, there is a lot less holding your breath while you fit that door cut-out or monitor opening. Precision in cutting and sewing make all the difference if you (or your client) like crisp flawless corners around your tension fabric and door openings.

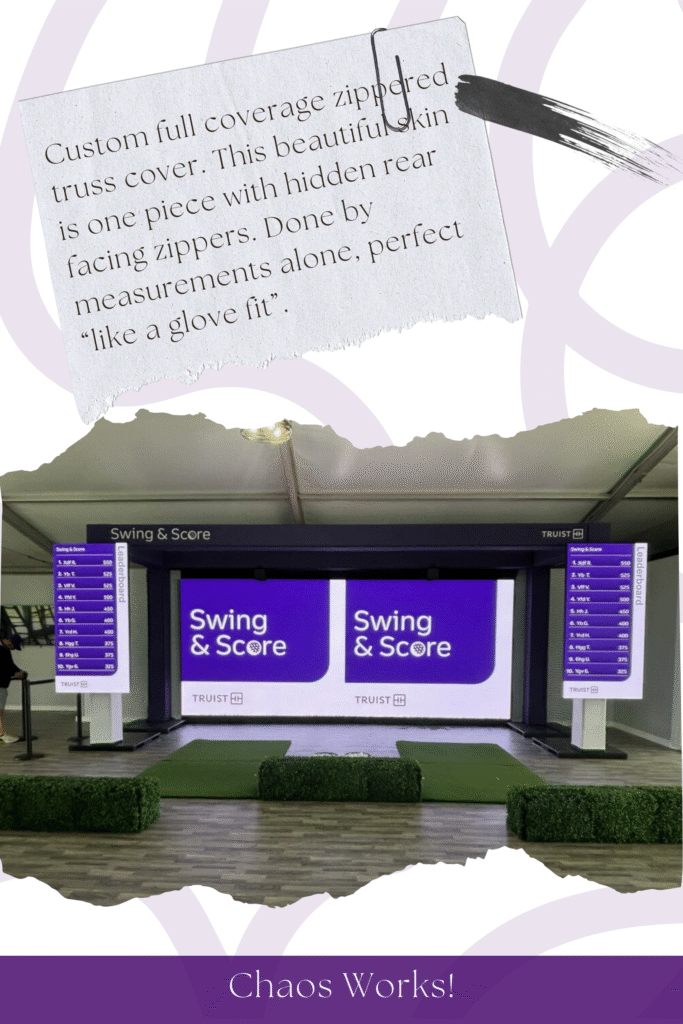

4. The Wrestling Match

The frame is up, the fabric is ready… and now it’s a two-person tug-of-war. Or worse, it’s so loose you’re MacGyver-ing it with clamps, staples and a prayer. Quality precision finishing means perfect fit—snug without the sweat.

5. Great! Except that seam…

That impressive oversized graphic became a showstopper for the wrong reason…the seam. It’s the opposite of invisible. It either doesn’t match (colors or alignment) or the seam is somehow pointing to one side of the frame giving a slight warp to the image. Professional printing finishing ensures the piece looks like one uniform image and not “pieced together”. I don’t know how many clients have given up on seamed graphics because they believe an invisible seam is impossible. It’s not, they just have not experienced the benefits of a quality fabric vendor oriented in expertise and precision.

The Payoff for Getting It Right

When your fabrics are finished and printed with care and expertise, you get:

- Flawless fit on every frame, every time.

- Consistent branding across multiple events and reorders.

- Faster installs with less frustration for your crew.

- Displays that show stop because they are flawless, they look timeless instead of temporary. The kind of display where you get to say “Yes, that’s fabric”.

- Happy clients who notice the difference (and keep coming back).

Why Fabricators Love Working With Us

We take your work as seriously as you do—and we’ve been in this game long enough to know the little details make the biggest difference.

We cut and sew with precision so fit is perfect.

We triple check the details before production so it’s right the first time.

We use advanced printing to keep colors bold, accurate, and photo-ready.

We quality-check every order before it leaves—because no one needs surprises on show day.

Our goal? To make your frames look their absolute best so you can focus on what you do best—building displays your clients can’t stop talking about.

Ready to ditch the fabric headaches? Make Chaos Works work for you.

Let’s get your next project printed, finished, and show-floor ready—without the misfits, color error, or wrestling match.